Beer Sensory Skills 101 | Infections | LAB

This article is part of a series of lessons and exercises that focus on enhancing your sensory skills to better recognize and address brewing problems. By training your sense of smell, taste, mouthfeel, etc., you will have a better understanding of identifying off-flavors/aromas and their causes, which can greatly assist you when looking for solutions to these problems. This blog series will come in many parts dealing with Yeast, Hops, Malt, Water, Infections/Contaminations, and Miscellaneous issues.

Each lesson includes an exercise in a separate tab to assist you in developing your palate and other senses to better detect these flavors, aromas, etc.

Lesson 5.1- Infections: Sour/LAB - When the Pucker Isn't Intended

What is "LAB":

Lactic acid bacteria (LAB), particularly species like Lactobacillus and Pediococcus, are primarily responsible for souring beer. These bacteria produce lactic acid as a metabolic byproduct during fermentation. The presence of lactic acid leads to a decrease in pH, resulting in the characteristic tartness or sourness associated with sour beers.

While some beer styles, such as Berliner Weisse, Gose, and certain Belgian sour ales, intentionally utilize LAB for their sour flavor profile, contamination by these bacteria in other beer styles can lead to unintended souring and off-flavors. LAB can thrive in low-oxygen environments, making them particularly problematic if sanitation practices are not rigorous or if brewing equipment is not properly cleaned and sanitized.

In contrast, wild yeast strains like Brettanomyces can also contribute to souring beer, but they typically produce more complex flavor profiles beyond simple acidity. Brettanomyces can produce flavors described as funky, earthy, or barnyard-like, in addition to contributing to acidity over time. Brettanomyces and other wild yeasts will be discussed in detail in another lesson. Overall, while both LAB and certain wild yeast strains can contribute to souring beer, LAB are the primary bacteria responsible for intentionally sour beer styles and are often associated with straightforward acidity in contaminated beers.

The Chemistry:

LABs sour beer through a process known as "lactic acid fermentation". In this chemical transformation, LAB metabolize the sugars present in the beer wort, typically maltose and maltotriose, through enzymatic reactions. Once introduced to the wort, LAB breaks down the sugars into simpler forms through enzymes like amylases and glucoamylases. These simpler sugars are then fermented by LAB, leading to the production of lactic acid as the primary end product.

During fermentation, LAB converts glucose into pyruvate through glycolysis, a process that does not produce carbon dioxide or ethanol. Pyruvate is subsequently converted into lactic acid, which accumulates in the beer, resulting in increased acidity and the characteristic sour taste associated with sour beers.

Aside from lactic acid, LAB may also produce additional flavor compounds during fermentation, including diacetyl, acetic acid, esters, and phenols. The specific flavor profile produced by LAB can vary depending on factors such as the strain of bacteria used, fermentation temperature, and wort composition.

Overall, lactic acid fermentation by LAB is central to the production of sour beers, contributing to their unique flavor profile and acidity. Understanding the chemical processes involved in souring beer is essential for brewers looking to create authentic and high-quality sour beer styles. But understanding these chemical processes also helps the brewer to avoid them in beers where they are undesired.

Avoiding LAB Contamination:

Avoiding contamination by lactic acid bacteria is essential for brewers who want to produce beer without unintended souring or off-flavors. Here are some key strategies for avoiding LAB in beer:

• Sanitation Practices: Maintain strict sanitation practices throughout the brewing process to prevent the introduction of LAB. Thoroughly clean and sanitize all brewing equipment, fermenters, hoses, and transfer lines to minimize the risk of contamination.

• Separate Equipment: Use separate equipment for handling sour beer and clean beer to prevent cross-contamination. Dedicated sour beer equipment should be clearly labeled and stored separately from clean beer equipment to avoid accidental contamination.

• Sour Beer Brewing Space: If brewing sour beers alongside clean beers, consider having separate brewing spaces or dedicated areas within the brewery for each. This helps minimize the risk of LAB transfer between different beer batches.

• Boiling: Boil brewing water before use to eliminate any potential LAB contamination. Boiling water can help sterilize it and reduce the risk of introducing unwanted bacteria into the brewing process.

• Prevent Oxygen Exposure: LAB thrive in low-oxygen environments, so minimize oxygen exposure during the brewing process. Use closed-system transfers and avoid splashing or aerating wort unnecessarily to prevent LAB from taking hold.

• Use Fresh Ingredients: Ensure that all brewing ingredients, including malt, hops, and yeast, are fresh and free from contamination. Using high-quality ingredients sourced from reputable suppliers reduces the risk of introducing LAB into the brewing process.

• Monitor Fermentation Conditions: Maintain optimal fermentation conditions, including temperature control and yeast pitching rates, to create an environment less conducive to LAB growth. LAB thrive in warmer temperatures, so fermenting at lower temperatures can help inhibit their growth.

• Quality Control: Implement rigorous quality control measures to detect and address any signs of contamination early in the brewing process. Regularly monitor pH levels, taste samples throughout fermentation, and inspect for any visual signs of infection, such as pellicle formation.

By implementing these strategies and maintaining a vigilant approach to sanitation and quality control, brewers can minimize the risk of LAB contamination and produce clean, consistent beer batches without unintended souring or off-flavors. These infections will NOT harm you, but they can result in an undesirable tasting beer.

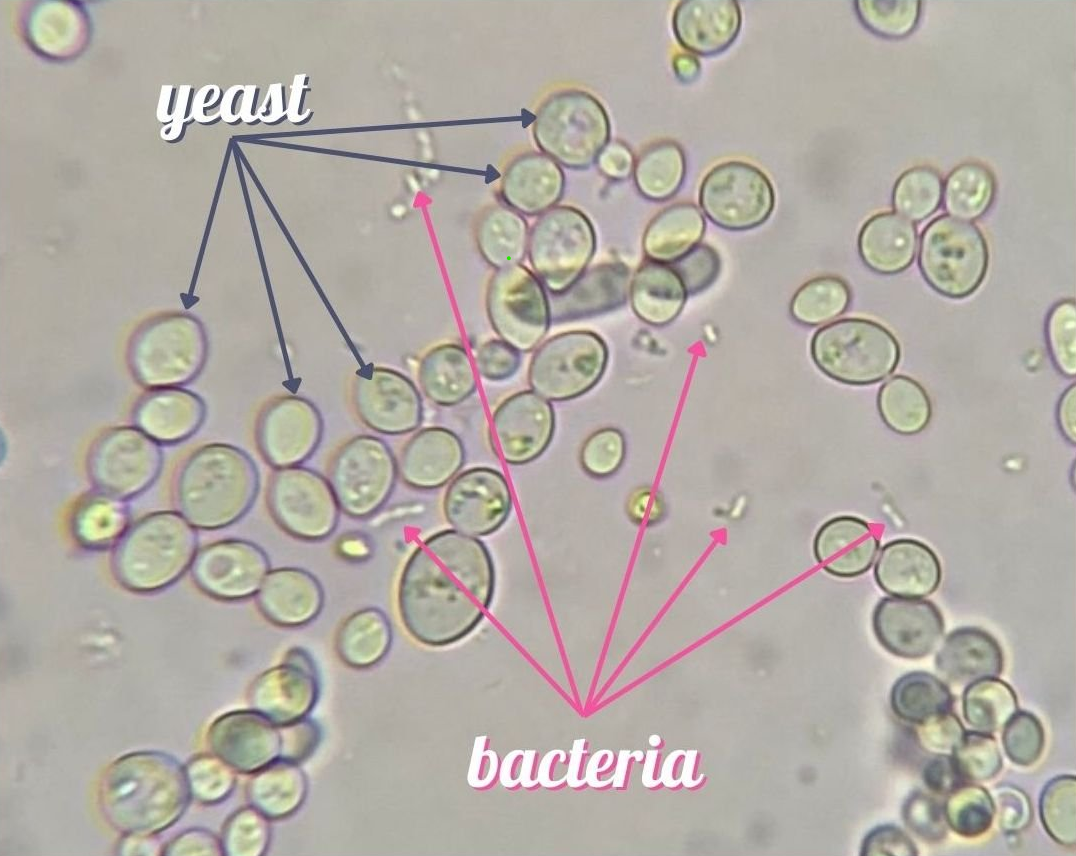

Bacteria shows up as "rod" shapes among the circular shapes of yeast cells under a microscope.

Lactobacillus infection causing a biofilm on top of the beer known as a "pellicle".

Detecting LAB Infections

Aroma:

• Lactic Sourness: LAB produce lactic acid during fermentation, which imparts a sour or tart aroma to the beer. This aroma is characteristic of sour beer styles but can be undesirable in other beer styles when present at high levels due to contamination.

• Yogurt-like: LAB fermentation can produce aroma compounds reminiscent of yogurt or sour milk. These aromas are often described as creamy, tangy, or slightly funky.

• Cheesy or Buttery: Certain strains of LAB, particularly Pediococcus, can produce aroma compounds such as diacetyl (a future lesson on diacetyl coming soon), which impart buttery or cheesy aromas to beer. These aromas are considered off-flavors when present at high levels.

• Acetic Adid or Vinegary: Acetic Acid will be discussed in a future lesson, but it's worth mentioning here that LAB may produce acetic acid through aerobic metabolism. The presence of acetic acid can result in vinegar-like aromas in beer, which are often undesirable unless intentionally incorporated into certain sour beer styles.

• Musty or Earthy: LAB contamination may also contribute to musty or earthy aromas in beer, which can be indicative of microbial spoilage. These aromas are generally considered undesirable and can detract from the overall drinking experience.

• Fruity Esters: Some LAB strains can produce fruity esters during fermentation, which contribute to complex aroma profiles. However, when present at high levels due to contamination, these esters can result in off-flavors that mask the desired characteristics of the beer.

Flavor:

• Lactic Sourness: LAB fermentation produces lactic acid, resulting in a tangy or puckering sourness in beer. This acidity is characteristic of sour beer styles but can be unwelcome in other styles when present due to contamination.

• Yogurt-like: LAB contamination can impart a creamy, tangy flavor reminiscent of yogurt or sour milk to beer. These flavors add a unique texture and acidity to the beer.

• Cheesy or Buttery: Certain strains of LAB, particularly Pediococcus, can produce diacetyl, a compound that imparts a buttery richness to beer. High levels of diacetyl due to contamination are considered off-flavors.

• Acetic Adid or Vinegary: LAB may produce acetic acid through aerobic metabolism, resulting in a sharp, vinegary flavor in beer. While intentional in some sour beer styles, high levels of acetic acid due to contamination are undesirable.

• Musty or Earthy: LAB contamination may contribute to earthy or musty flavors in beer, suggesting microbial spoilage. These flavors are typically unpleasant and can detract from the beer's overall taste.

• Fruity Esters: Some LAB strains can produce fruity esters during fermentation, adding complexity to the beer's flavor profile. However, when present at high levels due to contamination, these esters can result in off-flavors that overshadow the desired characteristics of the beer.

• Undesirable Metabolites: Some LAB strains can produce fruity esters during fermentation, adding complexity to the beer's flavor profile. However, when present at high levels due to contamination, these esters can result in off-flavors that overshadow the desired characteristics of the beer.

Overall, while LAB can positively influence certain beer styles when intentionally used, unintentional contamination by these bacteria can lead to off-flavors and undesirable taste profiles in others. Maintaining strict sanitation practices and quality control measures is essential for preventing LAB contamination and ensuring the production of clean, high-quality beer.

Sensory Training:

• Taste Comparisons: Compare sour beers intentionally soured with lactic acid bacteria (LAB) to clean, uncontaminated beers. Start by tasting the sour beer to familiarize yourself with the characteristic sourness and other flavors associated with LAB fermentation. Then, taste the clean beer to contrast the flavors and identify any differences. This practice allows you to distinguish between intentional souring and unintended contamination by LAB.

• Aroma Evaluation: Focus on comparing the aroma of sour beers intentionally soured with LAB to that of clean, uncontaminated beers. Take time to smell the sour beer first, noting the characteristic aromas such as sour, tangy, yogurt-like, or vinegar-like notes associated with LAB fermentation. Then, smell the clean beer to contrast the aromas and identify any differences. By practicing aroma evaluation in this way, you can develop your ability to detect LAB-related aromas and distinguish them from those present in uncontaminated beers.

• Consistency Testing: Test your ability to consistently detect LAB-related characteristics by periodically re-tasting the same sour beer samples and evaluating whether you can consistently identify the presence of sourness and other flavors associated with LAB fermentation. This helps reinforce your sensory memory and build confidence in your abilities.

• Practice and Feedback: Regularly practice tasting and evaluating sour beers for LAB-related flavors and aromas. Keep detailed tasting notes and compare them to known standards or guidelines to assess your proficiency. Seek feedback from experienced brewers, beer judges, or sensory experts to refine your sensory skills and improve your ability to detect off-flavors.

By incorporating these sensory training techniques into your routine and actively practicing your sensory skills, you can enhance your ability to detect LAB-related flavors and aromas in sour beers and develop a more discerning palate.

Recommended Beers For This Lesson

LABs, when controlled and balanced, can contribute positively to certain beer styles, adding complexity and depth to their flavor profiles. Here are some beer styles where lactic acid and LABs are often considered acceptable or even desirable:

Homebrewers need to keep sour beer production separate from regular brewing to prevent unintended contamination. Even small traces of lactic acid bacteria (LAB) can alter the flavor of regular beer, leading to off-flavors and disappointing results. By maintaining separation, homebrewers ensure consistency, quality, and enjoyment in each batch, simplifying equipment maintenance and preserving the integrity of their brews. NOTE: Pre-packaged Lactic acid on its own won't infect your other beers. It's the lactic acid bacteria that will. Our Mr. Beer kits only use pure lactic acid in the sour recipes to prevent cross-contamination.